Ice formation in transportation systems and infrastructure can cause serious problems, including malfunction and danger to life. Even though these systems are designed to withstand various environmental conditions, ice formation remains a critical issue.

Active anti-icing and deicing technologies are currently being used to combat this problem. However, these systems require a constant external power supply and are only effective once ice has already formed. Additionally, these systems are very sensitive and can detach quickly from the surfaces they are meant to protect.

To remedy this shortcoming, a research team at Austria’s Graz University of Technology (TU Graz) has developed a highly ice-repellent coating that adheres to a wide variety of materials and is very resistant to abrasion.

Researchers used a manufacturing technology called initiated chemical vapor deposition (CVD), which makes it possible for a strongly adhesive primer material to gradually transition into an ice-repellent compound. They were able to achieve a stepless transition between a strongly adhesive primer material and the ice-repellent compound by applying the two materials as a changing gas mixture to the surface to be coated.

Initially, the gas mixture consists purely of the primer material, but the proportion of the ice-repellent material is continuously increased during application, from 0 to 100%. The result is a dual-layer coating with a strongly adhesive underside and a top side preventing ice crystals from forming.

During their experiments, researchers discovered a new mechanism for preventing ice formation that has never been seen before. They found that the molecules in the coating they created arranged themselves in random horizontal and vertical patterns, which effectively stopped ice from forming.

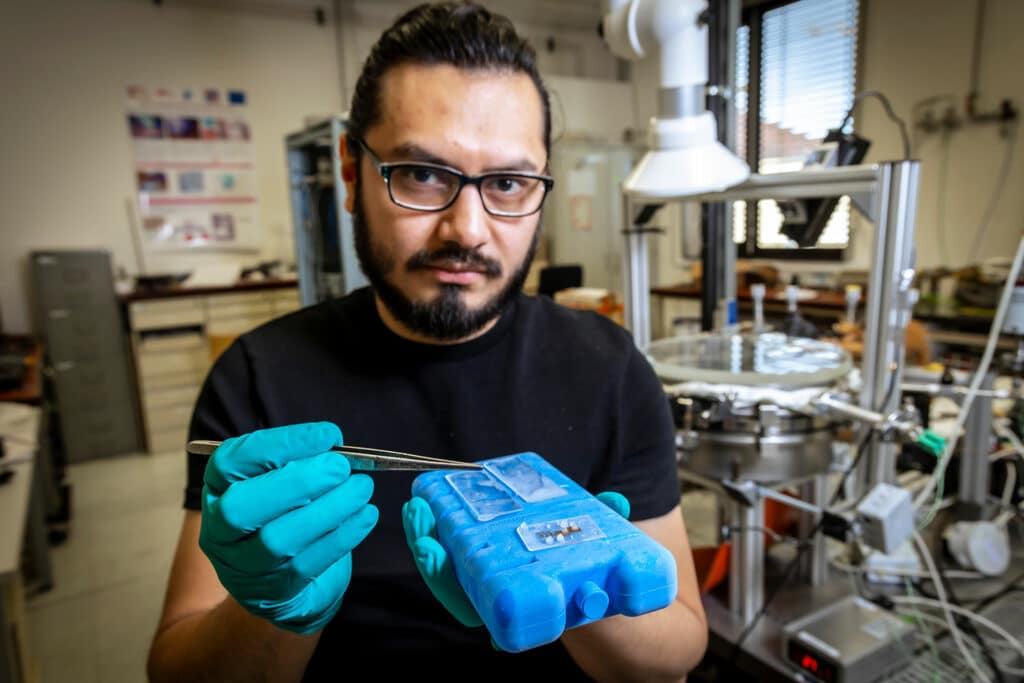

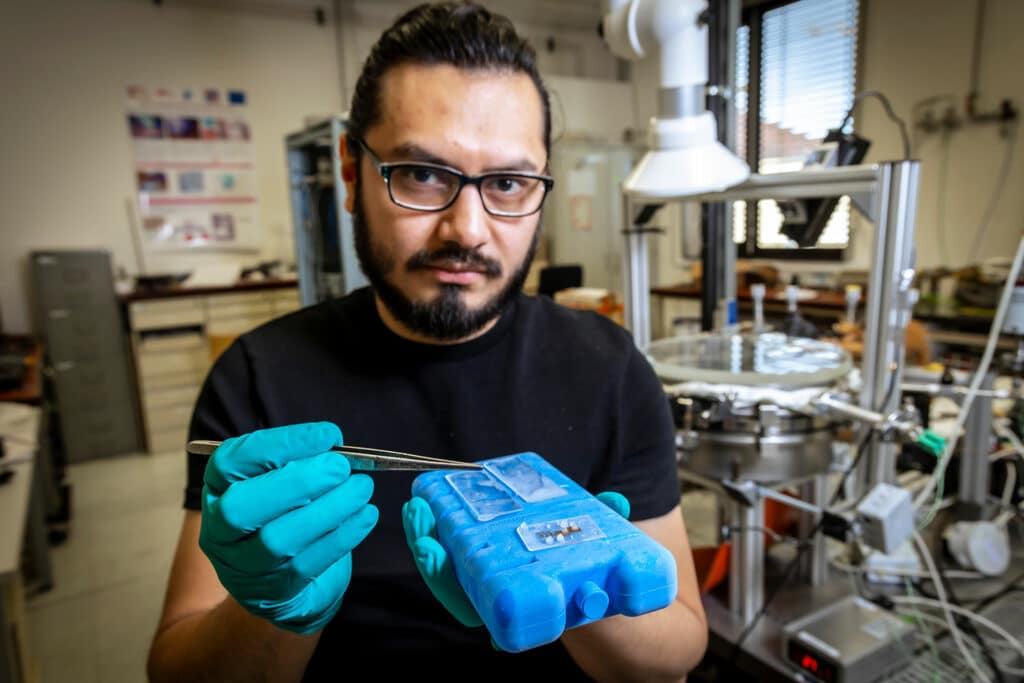

“The ice-repellent material consists of elongated molecules that adhere to the primer in a vertical or horizontal orientation,” explains Gabriel Hernández Rodríguez from the Institute of Solid State Physics at TU Graz. “The thicker we applied the material, the more random the alternation between vertical and horizontal molecules became. And the more random the arrangement at the surface, the greater the ice-repellent effect.”

While this could be useful to car owners in cold climates, the researchers have other applications in mind, such as speeding up the deicing of aircraft and protecting delicate sensing equipment from frost. The coating could also be used in the aviation industry to benefit sensors exposed to weather conditions that are disturbed by ice.

Journal reference:

- Gabriel Hernández Rodríguez, Mario Fratschko, Luca Stendardo, Carlo Antonini, Roland Resel, and Anna Maria Coclite. Icephobic Gradient Polymer Coatings Deposited via iCVD: A Novel Approach for Icing Control and Mitigation. ACS Applied Materials & Interfaces, 2024; DOI: 10.1021/acsami.3c18630